The development of abrasives has exploded during the last decade. We have seen an increase in material removal rate and better ergonomics when testing different grinders and abrasives. This article shows the correlation between different types of abrasives, with the productivity and ergonomic improvements that can be achieved by just changing your abrasive.

On top of that, manufacturers are always striving to design better and better grinders. The main objective being an increased productivity, and improved ergonomics by reducing vibration related injuries on the operator. During our productivity and vibration testing, made on/in real applications, we have seen that big improvements can be achieved within both areas, simply by changing the abrasive. By using the right type of abrasive for each application, you will be able to increase productivity. Furthermore you will reduce the risks of HAVS (hand-arm-vibration syndrome) related injuries such as vascular disorder, nerve injuries, muscle and joint disorder for the operators at the same time.

All tool manufacturers are by law responsible of minimizing the tool vibrations. This is done early in the design-phase and verified during predefined standard testing. The standardized test does not cover all applications and will therefore not always resemble the process vibrations. This is the same for all producers and it is a good way to compare the vibration level between different tool manufacturers. However, we have seen that the vibrations in the real application can be minimized and at the same time increase the productivity further by changing to another abrasive type.

Many companies are fighting this constant battle to improve the efficiency of their production and at the same time save money. This equation is not always easy to solve, especially if you don’t have a deep knowledge about the actual process itself.

For a lot of people abrasives all look the same, but don’t let looks fool you! We will show you a few simple steps how to find the right abrasive for you and your process which will save you money, increase the productivity and make the operators happy.

How to show difference

To show the differences in productivity and ergonomics, we set up a stock removal test where we continuously measured the vibration level and the feed force from the operator, as well as comparing the material removal rate.

The test in this case was performed with a 2.1 kW grinder with a declared total vibration value (3-axes value) according to the ISO 28927-1, of 4.8 m/s² with an uncertainty of 1.4 m/s².

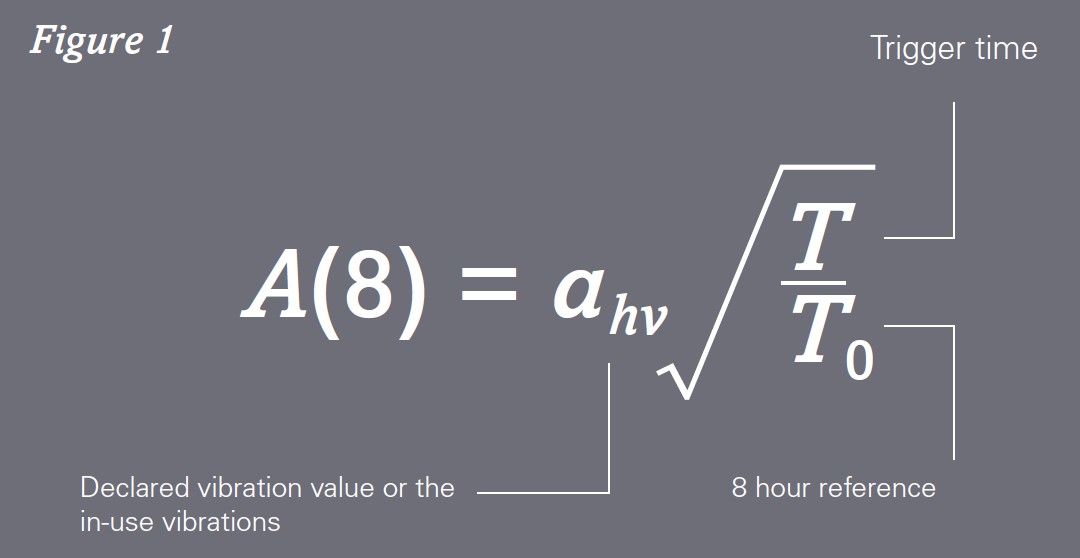

Vibration injuries are developed over time and once present they become permanent. The correlation between the risk of getting the injuries and the exposure is described in ISO5349-1:2001 as seen in figure 1.

Where A(8) is the daily vibration exposure, ahv is the declared vibration value or in-use vibration value (process), T is trigger time and T0 is a reference workday of 8 hours. A daily exposure value less than 2.5 m/s² means that the risk of getting injuries is low. A value above 2.5 m/s² means that the risk increases. In 2006, the European Union introduced regulation to control the exposure. All employers within the EU are now responsible for controlling and reducing the exposure of their employees.

The daily vibration exposure should be less than 2.5 m/s² and are never allowed to exceed 5 m/s².

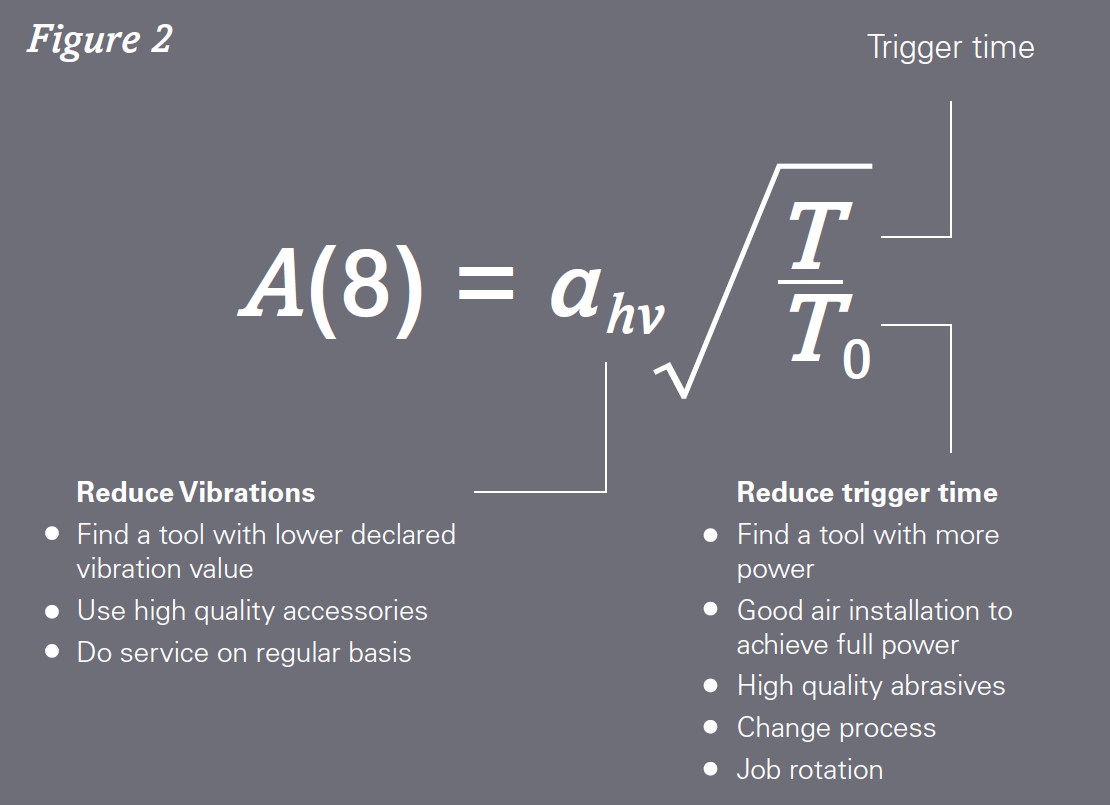

There are two ways of reducing the exposure; find a tool or a process to reduce vibrations, or reduce the trigger time. Examples on what to do is found in figure 2.

From calculations we can see that the calculated exposure time will be 1h and 20 min, for this grinder in order to be below 2.5 m/s2 and approx. 5h to reach the limit value. Another method is instead to have a look at the graph and we can find our vibration value and read out the allowed exposure time according to figure 3.

In this test we will investigate the effect that different abrasives has on vibration, feed force and material removal rate. When we have the new in-use vibration value, we can also recalculate the vibration exposure for the operator.

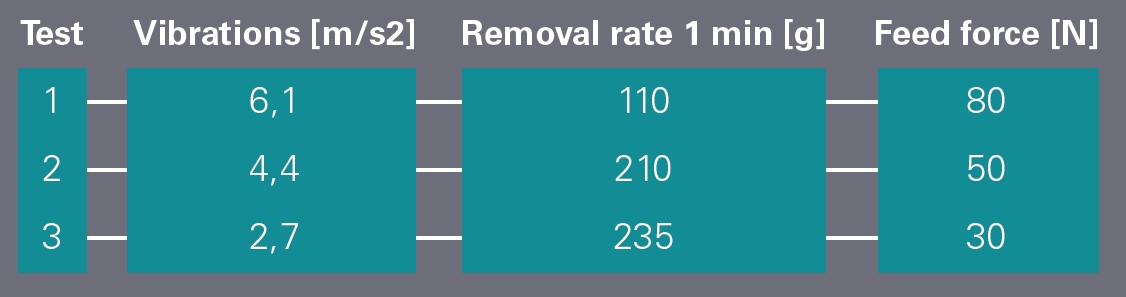

Test result

TEST 1: traditional depressed center wheel of premium quality with Aluminum Oxide grains. Average test result of three different operators.

The dark areas indicates that a lot of heat has been devolved in the material. We can also see that the vibration value is about the same as the declared value (4.8+1.4 = 6.2 m/s2).

So here we will get the same allowed exposure time as per the ISO calculations.

TEST 2: traditional depressed center wheel of premium quality with Ceramic grains. Average test result of three different operators.

Here we can see less heat development and a slightly finer surface.

In this case the operator can use the machine for approximately three hours from just reading of the graph, due to the selected abrasive. In this case the abrasives reduces the vibration exposure for the operator, and allows them to work for a longer time before reaching the limit.

But in combination with the increased productivity, the work will be finalized faster and further lower the vibration exposure!

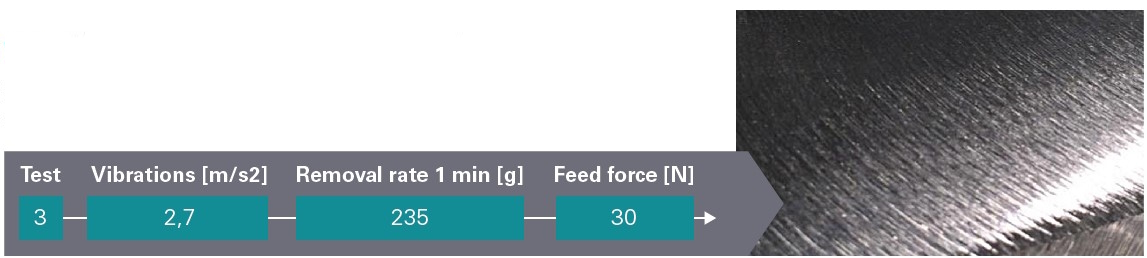

TEST 3: fiber disc type abrasive with ceramic grains: Average test result of three different operators.

The result is a very fine and flat surface, the heat has been on a very low level and no discoloring of the material.

In this case the vibration level decreases compared to the declared value, and the operator can now work for almost 8 hours in order to reach the vibration exposure limit. Just by selecting this abrasive.

So in this case the operator can work more than 6 times as long as if we would use the declared ISO value. Since the operator now also can finish the work faster with a better result, it will further lower the vibration exposure. Meaning less time at a lower vibration level – a true win-win situation!

Improvement depending on abrasive

We can clearly see that we get an improvement in material removal rate, when changing the type of abrasives. And the vibration is going down together with the feed force applied by the operator. This means a higher productivity and at the same time improve the ergonomics for the operator. Not only are the feed force and vibration values lower, the increased productivity shortens the vibration exposure as well. Over the entire working day, the operator will be more rested, and will be able to keep up the production rate at the wanted level, keeping an even quality.

As a distributor for many tool manufacturers we have the responsibility to suggest the most suitable tools (and abrasives as well) with as low vibrations as possible.

We test the tools according to the ISO 28927 series of standards, and declare this value. The ISO standard allows the customers to compare each and every tool against each other, knowing they are tested in the exact same way. Giving each user/customer the option to select the least vibrating tool available on the market.

This test also shows what great responsibility that comes with purchasing. And how important it is to select the correct type of abrasive, with the best quality in mind and not only the best price.

English

English  Tiếng Việt

Tiếng Việt